- Price per Carton

- Delivery within five days

- For Non-standard products please go to ever-hardware.com

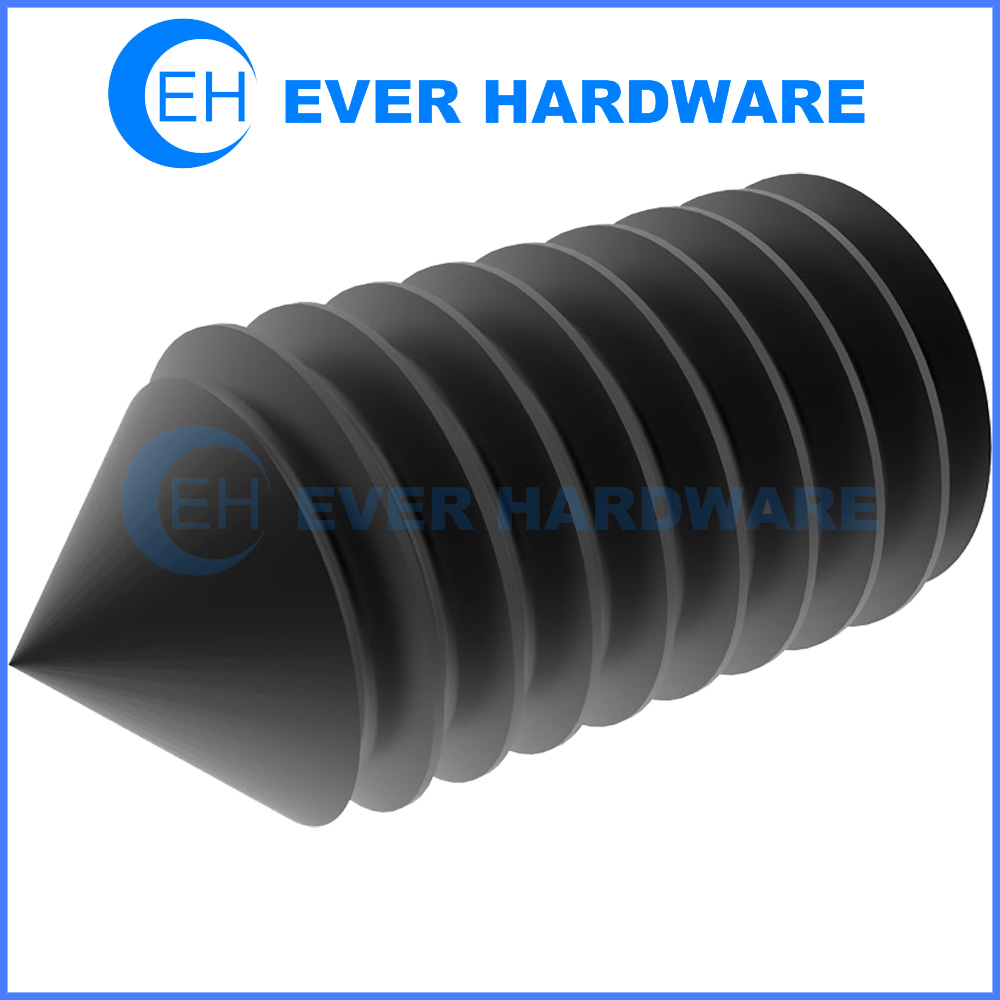

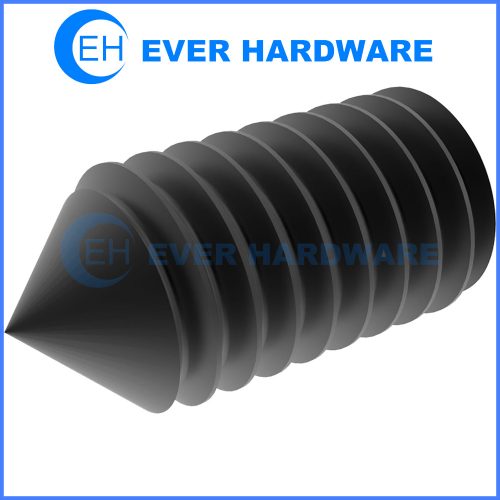

M4-0.7 Hex Socket Tip Point Set Screw DIN 914 Steel Black Oxide 45H

Price range: $64.99 through $172.99

Description

M4-0.7 Hex socket tip point set screw DIN 914 steel black oxide provides high strength, secure fastening, and adjustability at an affordable cost. Their durable construction and corrosion-resistant finish make them ideal for versatile applications in industrial and mechanical settings. Ever Hardware provides custom made fasteners and customizable packaging.

1. High Strength and Hardness: Made from 45H-grade steel, these screws provide exceptional tensile strength and hardness, making them suitable for high-stress and heavy-duty applications. They perform well in settings where vibration and mechanical loads are common.

2. Tip Point Design for Secure Grip: The tip point design enables the screw to dig into the mating surface, providing a firm and reliable grip. This makes them ideal for securing gears, pulleys, and collars on shafts, even in high-torque or dynamic environments.

3. Black Oxide Coating for Corrosion Resistance: The black oxide finish offers moderate corrosion resistance, protecting the screws from rust in indoor or mildly corrosive environments. It also enhances the screw’s appearance, providing a sleek, professional look.

4. Hex Socket Drive for Precision: The hex socket drive allows for precise torque application, reducing the risk of cam-out or stripping. This ensures efficient installation and adjustment, particularly in tight spaces or for components requiring frequent realignment.

5. Cost-Effective Solution: Compared to stainless steel or other premium materials, black oxide steel screws are more affordable while still offering excellent strength and reliability for general-purpose applications.

6. Non-Permanent Fastening for Adjustability: These screws are ideal for assemblies requiring periodic adjustments or maintenance. Their design allows for easy removal and reinstallation without damaging the mating surface.

7. Versatile Applications: DIN 914 screws are widely used in industrial machinery, automotive systems, and mechanical assemblies, ensuring secure connections in components under stress or vibration.

DIN 914 M4-0.7 Hex Socket Tip Point Set Screw is strong, durable fasteners designed for secure and adjustable connections.

| Thread Diamater | M4/4mm |

|---|---|

| Thread Pitch | 0.7 |

| Tip Type | Cone Point |

| Socket/Allen A/F | 2.02-2.045 |

| Material | Alloy Steel 40Cr |

| Grade | 45H |

| Finish | Black Oxide |

Additional information

| Weight | N/A |

|---|---|

| Length | 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 30mm |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.